Annual Cost Reduction Program

A process where a business will review their systems and materials once a year in order to cut costs and increase profits.

Bill of Materials (BOM)

The list of the components (along with their prices) needed to produce a product.

Burn-in Equipment

Equipment that tests the reliability of a component by running it for a prolonged period of time.

Compliance Testing

A set of tests that ensures the product meets the required standards either set by the government or by the industry.

First Article Inspection (FAI)

A method to review the initial build on a production run to ensure that all aspects of the product meet the customer’s detailed specifications.

Fixed Costs

Costs that do not change based on the quantity of units purchased; typically include factory margin, production setup, and compliance testing fees.

Flexible (Variable) Costs

Costs that can change depending on the number of units purchased or the type of materials used.

Freight Forwarder

A company that organizes shipments for businesses to get products from manufacturer to market.

Golden Sample

A perfectly made piece of the product created by the factory to use as a standard for when the product is produced at mass scale.

Incoming Quality Control (IQC)

The department at the manufacturing facility that reviews the quality of components before they are used in the production line.

Lead Time

The amount of time it takes to receive goods including timeline to purchase materials and delivery.

Logistics

The process and organization of creating, moving, and storing products.

Manufacturability

The degree in which a product design is able to be easily produced in a manufacturing facility.

New Product Introduction (NPI)

A program to help with the design, creation, and launch of a new product.

Non-Recurring Engineering (NRE)

One time only payment for engineering services.

Outgoing Quality Control (OQC)

The department that reviews the quality of the products manufactured before leaving the facility and are shipped to the customer.

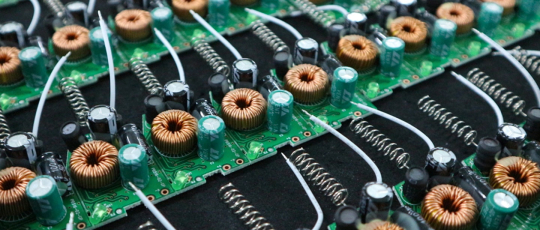

Printed Circuit Board (PCB)

A thin flat sheet of plastic that includes gold plated circuit drawings and houses additional components that control a device's hardware.

Printed Circuit Board Assembly (PCBA)

The process of placing and securing additional components to the PCB.

Production

The stage of manufacturing where the product is created and assembled on a large scale.

Prototype

A physical model of the product created during the design phase.

Risk Mitigation

A way of avoiding or preparing for the effects of potential threats or risks.

Scaling

The increase in units produced at a manufacturing facility based on the customer’s increased demand.

Sourcing

The process of finding and selecting businesses or components within a specified set of guidelines.

Surface Mount Technology (SMT)

A manufacturing method where components are placed on the surface of a PCB. SMT is completed by a machine allowing for more complex PCBA builds, lower margin of error, and efficient repeatability.

Tooling

The process of preparing a metal or plastic mold necessary to create a custom part.